You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

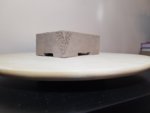

First ever pot. Thoughts?

- Thread starter Mihai

- Start date

Brian Van Fleet

Pretty Fly for a Bonsai Guy

Nice start. The western world doesn’t need any more wheel-thrown potters, so it’s good to see slab-built construction.

CamdenJim

Shohin

You get major points for careful planning, and even more points for what appears to be careful follow through and construction.Hey guys. Tried my hand at pot making tonight. First time apart from diddling some clay at a friend's workshop.

Few hours later, this 15/20 cm thing came out. Thoughts and critiques?

WELL DONE!

coachspinks

Chumono

Great job!

Tieball

Masterpiece

Nice work. I like the drawings....always good to have a plan. And, well, I’m a visually oriented person that draws a plan, or at least a detail scotch, for almost everything I make.

And, A+ for the photography.

And, A+ for the photography.

Mihai

Shohin

Thanks for the replies guys. Hoping the next will look even more refined.

Got a question for you potters out there: my choices of clay are pretty limited as in I can only get clay from one manufacturer (Georg&Schnider).

I chose a body with 25% fine grog (chamote) with high plasticity and low absorbtion ~1-2% at 1250.

This should be enough to make it frost proof. Correct?

Got a question for you potters out there: my choices of clay are pretty limited as in I can only get clay from one manufacturer (Georg&Schnider).

I chose a body with 25% fine grog (chamote) with high plasticity and low absorbtion ~1-2% at 1250.

This should be enough to make it frost proof. Correct?

thams

Omono

Thanks for the replies guys. Hoping the next will look even more refined.

Got a question for you potters out there: my choices of clay are pretty limited as in I can only get clay from one manufacturer (Georg&Schnider).

I chose a body with 25% fine grog (chamote) with high plasticity and low absorbtion ~1-2% at 1250.

This should be enough to make it frost proof. Correct?

What are you firing to? The key is to fire the pot at a temperature that results in vitrification. For example, if you have a clay that vitrifies at cone 10, but you only fire to cone 6, then it will not be frost-proof. However, if the clay is rated to cone 6 in the same circumstance, then the clay will vitrify. I guess the real question is what are your plans for firing?

rockm

Spuds Moyogi

Ditto! on the wheel thrown stuff (enough is enough ;-)) Nice work.Nice start. The western world doesn’t need any more wheel-thrown potters, so it’s good to see slab-built construction.

Mihai

Shohin

Bisque will be at 960C and final firing will be 1250-1260C. This is cone 8 I believe? I'm dependent on these temperatures for the moment because I don't have a kiln and I'm relying on some friends who will fire them with their own wares for which they use these temps.

It should be vitrified at this point according to the manufacturer. Vitrification is at 1240C and max temp is 1300C.

It should be vitrified at this point according to the manufacturer. Vitrification is at 1240C and max temp is 1300C.

thams

Omono

Bisque will be at 960C and final firing will be 1250-1260C. This is cone 8 I believe? I'm dependent on these temperatures for the moment because I don't have a kiln and I'm relying on some friends who will fire them with their own wares for which they use these temps.

It should be vitrified at this point according to the manufacturer. Vitrification is at 1240C and max temp is 1300C.

You should be good to go then!

substratum

Shohin

Very nice. Looking forward to seeing the final product!

Smoke

Ignore-Amus

Mihai

Shohin

Vin

Imperial Masterpiece

just.wing.it

Deadwood Head

Wow, very nicely done!

I like how the bottom corners overhang the feet a bit, on the first one...

It's unusual and unique, just great!

I like how the bottom corners overhang the feet a bit, on the first one...

It's unusual and unique, just great!

Mihai

Shohin

Holy SHIT Batman! Two thumbs up from @Smoke ! He must feeling amorous or something.The second pot is really nice in my opinion.

Any critique? If not, I'll just keep this going and assume I'm doing OKish.

Mihai

Shohin

I'd like to say that it was intentional but really just a happy accident. Liked them too so they stayed.Wow, very nicely done!

I like how the bottom corners overhang the feet a bit, on the first one...

It's unusual and unique, just great!

just.wing.it

Deadwood Head

I kinda thought that may have been the case...which is fine... doesn't change my opinion at all.I'd like to say that it was intentional but really just a happy accident. Liked them too so they stayed.

Happy accident, like you said!

Vin

Imperial Masterpiece

I'm not skilled in pottery so all I can say is it seems like more time should be spent in surface preparation prior to firing. All those imperfections are going to be very obvious after firing. If that's what you're after then fine but if not then better address it now.

Similar threads

- Poll

- Replies

- 65

- Views

- 6K